Mertech Marine’s Odyssey

From breakdowns to breakthroughs

IMPACT

- Increased technician and operator accountability

- Decreased downtime and technician response times

The Customer Journey

About The Customer

Mertech Marine, established in 1998, is a leader and innovator of turnkey solutions in the submarine telecommunication industry, with a core focus on cable recovery, dismantling and recycling.

Boasting an impressive global portfolio of out-of-service cables spanning the Atlantic, Mediterranean, Pacific and Indian Oceans, Mertech has successfully recovered and recycled up to 60 000 kilometres of cable to date. Their marine division boasts a fleet of 3 custom vessels, offering cable freighting and general cargo services.

Their environmentally friendly facility in Gqeberha, South Africa, employs 80 to 120 workers, driving the mechanical dismantling of submarine telecommunication cables in an eco-conscious manner.

A Digital Checkpoint

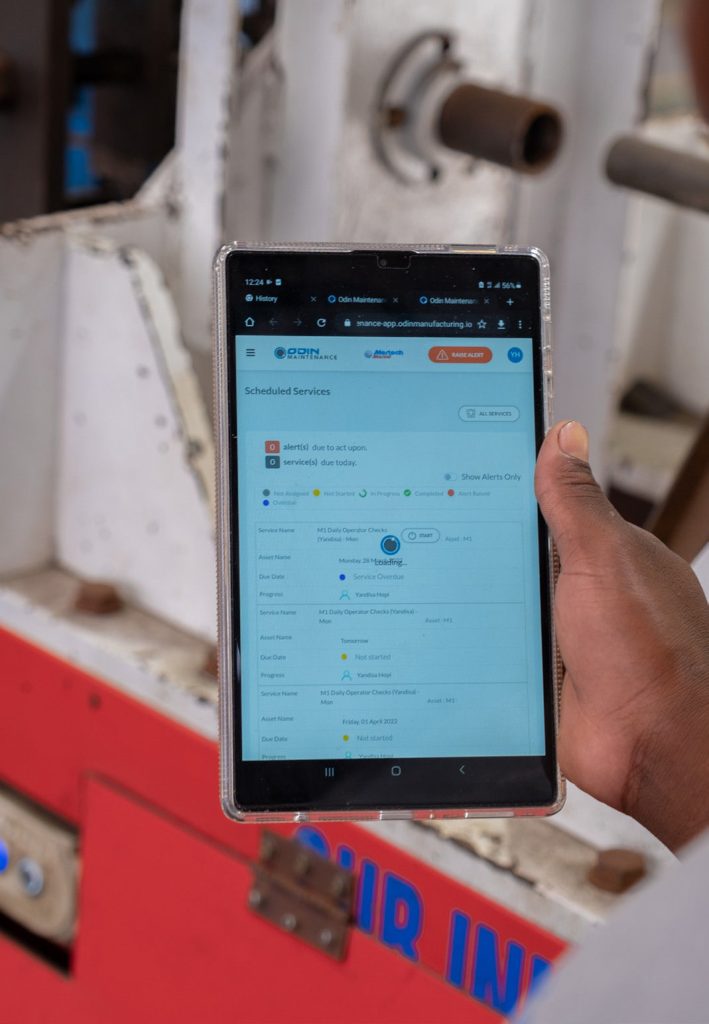

To mitigate these challenges, Mertech introduced ODIN Checkpoint, a versatile cloud-based solution that seamlessly integrated into their existing software stack.

This highly adaptable and agile application served as a beacon of structure for their maintenance teams. Tablets loaded with the software were deployed, and the maintenance team and plant manager underwent a comprehensive, guided onboarding process.

All machine services have been meticulously documented within the system, which triggers timely alerts to technicians for scheduled services. While on-site, technicians gain access to step-by-step service guides, inclusive of specific, critical focal points at a facility that may require additional attention. The services can be set up to be as simple or as thorough as needed, where machine

specifications and tolerances can be listed, images of any issues taken, and escalated through the Raise Alert function, if there is an unplanned downtime event. This digital transformation of the maintenance function ushered in a paperless approach to comprehensive maintenance management.

Downtime Disaster

Mertech was experiencing several issues relating to machine downtime events that affected the available productive time of equipment, which, in turn, negatively impacted production rates.

They had initially attempted to track this data manually, but this paper-based system created its own set of challenges, such as not having access to the relevant documents in the event of a breakdown, having no effective way to notify anyone that a breakdown had occurred, and no way of knowing if a piece of equipment had been fixed by the maintenance technicians.

This lack of a standardised and controlled system created issues with accountability, as there was no means for tracking maintenance services, or the technician concerned.

Digital Solution

Enhanced Visibility and Informed Decision-Making

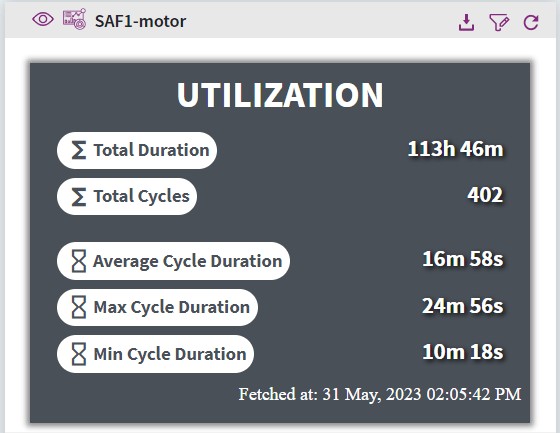

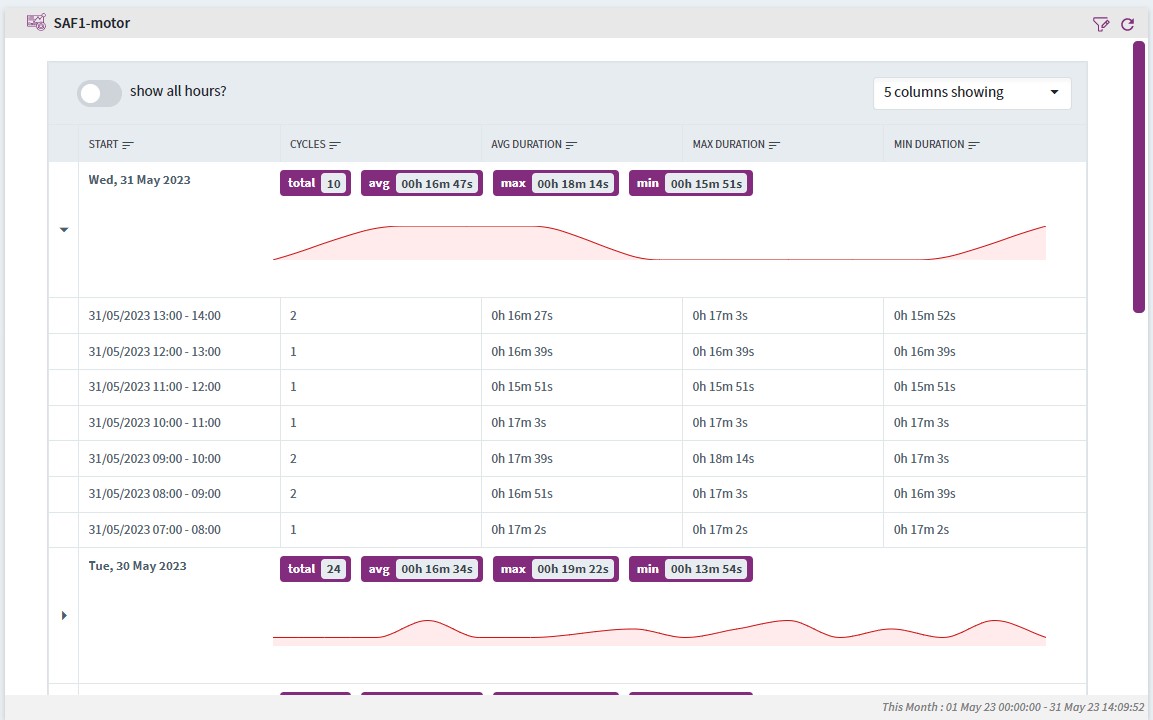

ODIN Checkpoint offers a suite of interactive dashboards that empower users to gain valuable insights into the operation of linear welders.

Users can:

Get a holistic view of production performance:

Monitor the overall usage of the welding machines over defined periods e.g. the total number of welds conducted during each hour of a day. This feature helps to determine whether production targets are being met and identify periods of inefficiency, such as prolonged idle times or loading activities.

Access accurate info for calculating part production costs:

The dashboards facilitate a detailed analysis of welding costs by estimating the expenses associated with individual welds. This estimation is based on the average time required to complete a weld.

Additionally, users can derive insights into the number of welds needed to manufacture specific parts, thereby contributing to informed decision-making and cost-effective planning.

The Data You Know

ODIN Checkpoint’s setup organically creates a single point of reference offering enhanced visibility into asset status, downtime events, and service completion.

Adeptly addressing previously inaccessible data, the user-friendly dashboard and Kanban-style visual elements expedite real-time data access from a central hub. This optimised setup not only facilitates transparency but also empowers technicians to proactively perform consistent, planned maintenance.

By leveraging ODIN Checkpoint’s tools for setting, monitoring, and controlling maintenance and service tasks, asset effectiveness is optimised, and lifespan is prolonged, thereby outlining a coherent pathway toward superior maintenance practices.

Conclusion

Mertech’s transition to ODIN Checkpoint epitomises a paradigm shift from downtime chaos to orchestrated efficiency.

This cloud-powered solution, with its guided servicing, empowers teams, catalyses transparency, and illuminates asset health through its cohesive dashboard.

This evolution paved the way for streamlined operations, prolonged asset lifespan and responsible industry stewardship.