About Us

Built on decades of automation and digital manufacturing excellence

5M+ products

built with ODIN Workstation

10,000+

devices

connected

Over 30

years

experience

Backed globally

by Tech Mahindra

(90+ countries, $6.2B turnover)

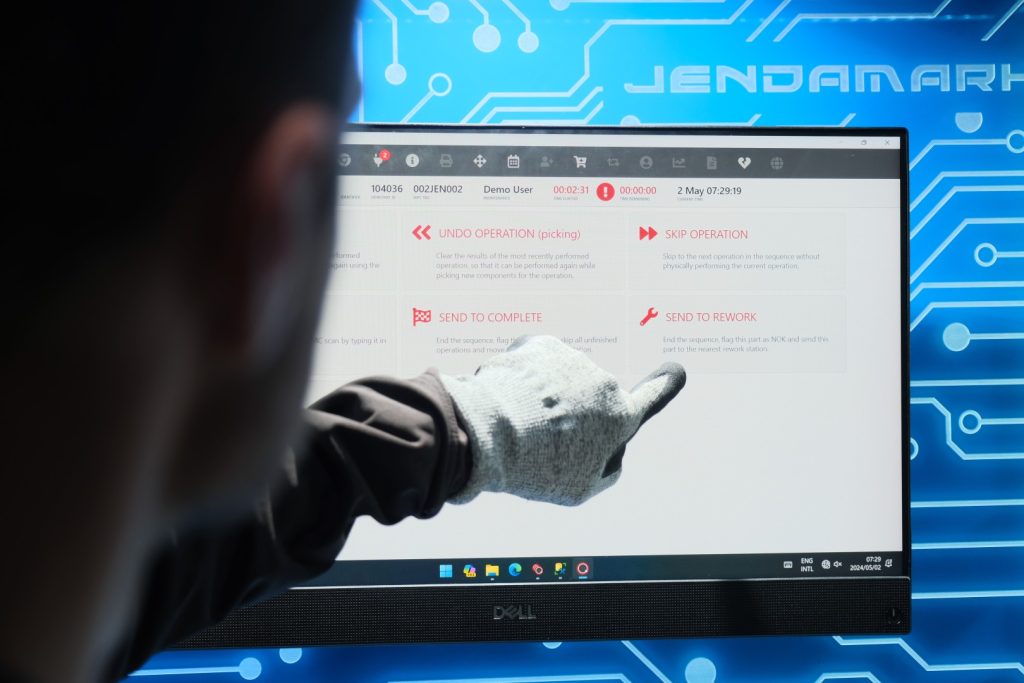

ODIN Workstation

was created to solve a clear problem in factories. Operators needed better guidance. Supervisors needed clear visibility. Managers needed accurate data from every step on the line.

History

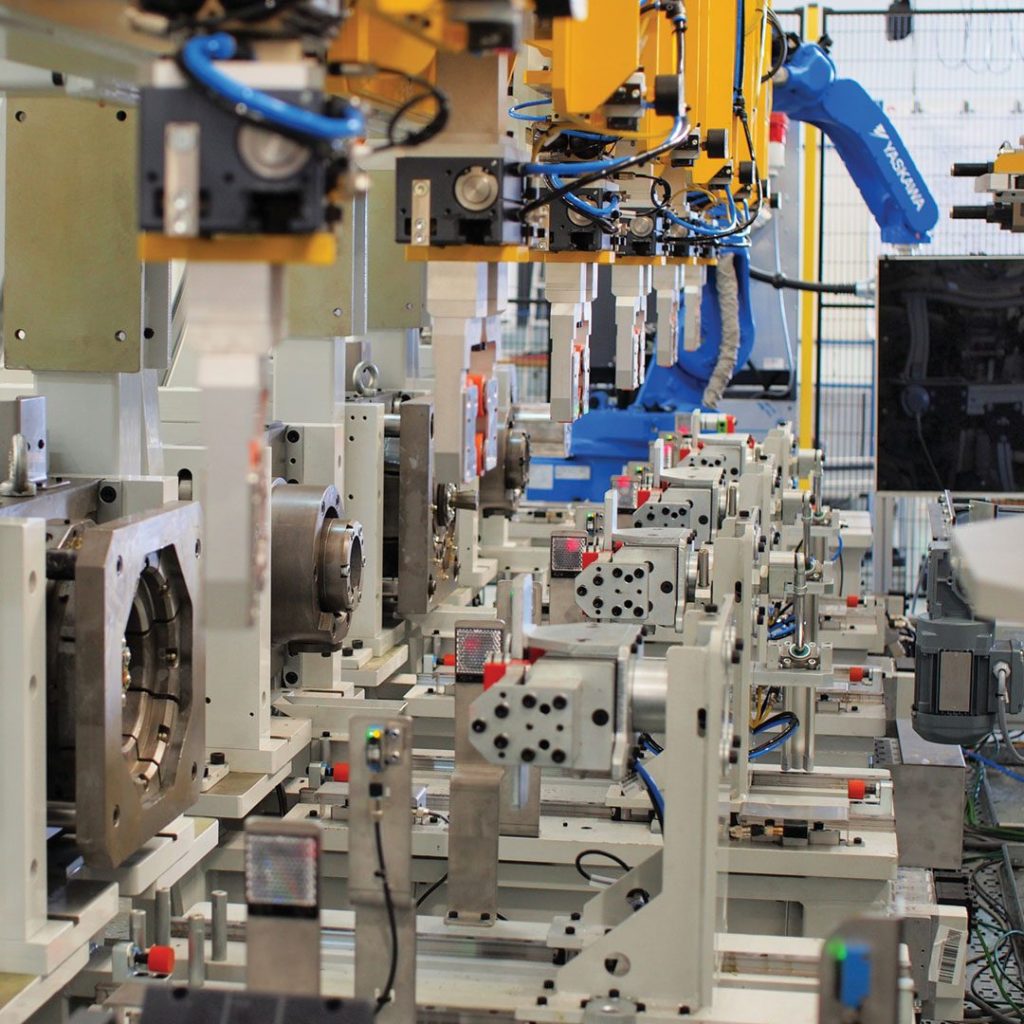

The system began inside Jendamark. For more than 30 years, Jendamark has built complex assembly systems for the automotive industry. Their teams work inside factories worldwide, where they see how production lines operate in real conditions. They also see the impact of unclear processes, slow training, and inconsistent quality checks.

To fix these issues in their own facilities, Jendamark built a single digital solution. It connected people, process, and machines in one place. It guided operators through each step, reduced mistakes, improved training, and created reliable traceability.

That internal solution became ODIN Workstation. It proved itself on real lines with real operators. As other manufacturers saw the results, they began asking for access to the same system.

Today ODIN Workstation is available to any factory that wants simple, effective control over quality, performance, and training.

From internal innovation to

global manufacturing software

ODIN Workstation began as an internal project to improve production efficiency, reduce errors, and make operator training faster and more consistent. The results were remarkable. The facilities that Jendamark developed saw higher throughput, shorter onboarding time, and real-time visibility into every step of the build process.

Customers took notice and Jendamark’s foray into digital manufacturing evolved into a globally deployed digital assembly workstation, a platform that helps manufacturers increase output without new machines, train anyone in days, and achieve audit-ready compliance with ease.

Today, ODIN Workstation empowers discrete manufacturers in automotive, EV battery, and other industrial assembly sectors to scale smarter with digital work instructions, paperless manufacturing, and real-time process control.

Our philosophy

We believe manufacturing excellence happens when people are empowered by clear, connected, and intelligent systems. ODIN Workstation gives operators digital clarity, managers real-time data, and businesses full control of their assembly process.

From process optimisation to on-the-job training automation and quality traceability, our goal is to help every factory achieve smarter, more sustainable growth, without increasing headcount or capital expenditure.

Backed globally by

Tech Mahindra

(90+ countries, $6.2B turnover)

This global partnership ensures every ODIN implementation is secure, supported, and ready for enterprise-scale integration. Together, Jendamark and Tech Mahindra deliver the reliability and scalability that modern manufacturers expect from an Industry 4.0 solution.

Trusted by Leading Manufacturers Worldwide

From automotive giants to complex harness builders, Odin Workstation has proven results.

Customers report faster training, 40%+ output increases, fewer errors, and stronger customer confidence.

Scale smarter with us

If your team is looking to increase throughput, train faster, or reduce production errors, start with our free guide:

The Smart Scaling Playbook: A practical resource that explains how leading manufacturers unlock 30 to 50% more output using digital work instructions and guided assembly.

Learn how to scale your assembly operations without adding new machines or headcount.